Section 3 Site Investigation Design and Implementation: Overview

NOTE: This page is under construction. See the PDF downloads for Section 3.

Interim Final – June 2024

Section 3.0 Application Scope

Section 3.1 Terms and Definitions

3.1.1 Risk-Based Site Investigation

3.1.2 Site Investigation Systematic Planning

3.1.3 Conceptual Site Model (CSM)

3.1.4 Decision Unit

3.1.5 Source Area DU

3.1.6 Boundary Area

3.1.7 Exposure Area DU

3.1.8 Heterogeneity

3.1.9 Gy’s Sampling Theory

3.1.10 Increment

3.1.11 Multi Increment Sample®

3.1.12 Discrete Sample

Section 3.2 Systematic Planning Process

3.2.1 Step 1: Overview of Systematic Planning Steps

3.2.2 Step 2: Identify Site Investigation Objectives and Chemicals of Potential Concern

3.2.3 Step 3: Determine Data Information Needs

3.2.4 Step 4: Designate Decision Units

3.2.5 Step 5: Prepare Decision Statements/Judgements

3.2.6 Step 6: Develop and Implement Sample Collection and Analysis Plan

3.2.7 Step 7: Assess Data Quality

3.2.8 Step 8: Determine Potential Environmental Hazards

3.2.9 Step 9: Improve CSM and Propose Next Action Proposal

Section 3.3 Designation of Decision Units

3.3.1 Exposure Area DUs

3.3.2 Contamination Source Area DUs

3.3.3 Contamination Source Boundary Area DUs

3.3.4 Excavations and Stockpiles

3.3.5 Sediment Decision Units

Section 3.4 Sampling and Analysis Plans

3.4.1 SAP Outline

3.4.2 Sample Collection Strategy

3.4.3 Health and Safety Plans

3.4.4 Quality Assurance Project Plans

Section 3.5 Site Investigation Reports

Section 3.6 Decision Unit Characterization

3.6.1 Use of Multi Increment Samples to Represent DUs

3.6.2 Sample Mass, Increment Number, Quality and Distribution

3.6.3 Sample Collection Area Preparation

3.6.4 Collection of Soil Samples

3.6.5 Field Sampling Quality Control

Section 3.7 Laboratory Sample Processing and Testing

Section 3.8 Data Quality Evaluation

3.8.1 Overview

3.8.2 Review of Sample Collecting and Processing Methods

3.8.3 Review of Replicate Data Precision

3.8.4 Additional Manipulation of Multi Increment Sample Data

3.8.5 Common DU-MIS Investigation Errors and Problems

Section 3.9 Using Data For Decision Making

3.9.1 Environmental Hazard Evaluation

3.9.2 Follow-Up Recommendations

This standard applies to field sampling and laboratory sample preparation for investigations of contaminated soil. Although the methodologies and examples presented focus on soil, the general concepts and approaches are applicable to investigations of all forms of particulate matter, including sediment. The methods described likewise apply to all types of contaminants including non-volatile and volatile chemicals and surface as well as subsurface conditions.

Return to the Top of the Page

3.1 TERMS AND DEFINITIONS

3.1.1 RISK-BASED SITE INVESTIGATION

The investigation and collection of sample data in a manner that directly reflects and answers questions related to the assessment of risk or to the optimization of remedial activities designed to address identified or anticipated risks. “Decision Units” and “Multi Increment® Sample” collection methods are an important part of a risk-based site investigation. The term “Multi Increment” is a registered trademark of EnviroStat, Inc.

3.1.2 SITE INVESTIGATION SYSTEMATIC PLANNING

The step-by-step process of compiling background information and developing a site conceptual model that is subsequently used to prepare a sampling and analysis plan and guide investigation efforts in the field.

3.1.3 CONCEPTUAL SITE MODEL (CSM)

A schematic or written summary of site conditions and risk to human health and the environment based on information compiled during the Systematic Planning process and updated as additional site data are collected.

3.1.4 DECISION UNIT

An area and volume of soil or sediment about which a decision regarding risk and/or remediation is to be made based on sample results.

3.1.5 SOURCE AREA DU

Refers to a specific area of known or suspected contaminated soil or sediment presumed to pose a significant risk to human health and the environment. Source areas are normally identified and tested separately during a site investigation to optimize remediation efforts.

3.1.6 BOUNDARY AREA DU

Refers to a peripheral and anticipated clean area of soil or sediment immediately adjacent to a known or suspected source area and is intended to confirm the lateral and/or vertical extent of the contamination.

3.1.7 EXPOSURE AREA DU

A specific area frequented by human or ecological receptors that is tested and used to quantitatively assess risk. Risk is quantified based on the mean concentration of the contaminant within the entire exposure area.

3.1.8 HETEROGENEITY

The variability of contaminant distribution and concentrations between individual particles of soil (“compositional heterogeneity”) and in the distribution of the contaminant within the DU area and volume of soil or sediment as a whole (“distributional heterogeneity”).

3.1.9 GY’S SAMPLING THEORY

Statistical-based theory of the collection of samples of heterogeneous, particulate matter such as soil or sediment developed by Pierre Gy. Gy’s sampling theory includes strict requirements for the collection, processing and analysis of samples.

3.1.10 INCREMENT

Refers to single masses of soil or sediment collected within a DU that are combined to prepare a Multi Increment Sample.

3.1.11 MULTI INCREMENT SAMPLE®

Refers to a sample prepared by the collection and combination of multiple increments of soil from a single DU. A Multi Increment sample is required to have a minimum mass and must be processed in accordance with Gy’s sampling theory to produce representative data. Multi Increment® is a registered trademark of EnviroStat, Inc. Investigations that strictly adhere to guidance presented in this document may and should use the term in associated reports.

3.1.12 DISCRETE SAMPLE

Refers to a sample collected from a single point within a targeted area with no requirements for minimum mass or thorough processing by a laboratory. A discrete (or “grab”) sample can be thought of as a “single increment” sample. Discrete sample data are not reliable for delineation of contamination or assessment of risk.

Return to the Top of the Page

3.2 SYSTEMATIC PLANNING PROCESS

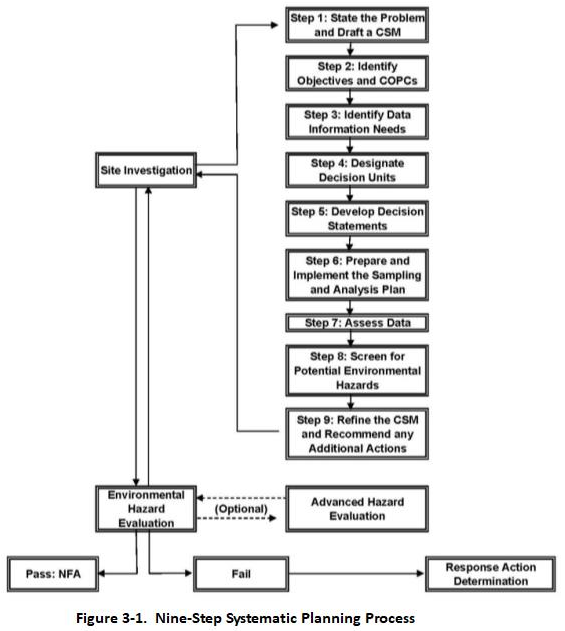

The Systematic Planning process consists of nine sequential steps designed to ensure that a well-thought-out workplan is prepared prior to the actual collection of samples in the field (Figure 3-1): (1) Define the site investigation scope and establish a preliminary conceptual site model (CSM); (2) Identify known or suspect hazardous chemicals; (3) Determine data information needs; (4) Designate DUs; (5) Develop DU decision statements; (6) Develop and implement sampling and analysis plan; (7) Assess the quality of the data; (8) Determine potential environmental risk/hazards and (9) Revise CSM and propose recommendations for next steps.

3.2.1 STEP 1: DEFINE SITE INVESTIGATION SCOPE & ESTABLISH PRELIMINARY CONCEPTUAL SITE MODEL

Review site history and available environmental data. Consult with past or current employees or other people familiar with operations at the site/facility. Review available information on past chemical use and known or potential releases. Consider preliminary screening of the site by collection of Multi Increment samples from a small number targeted DUs and use of field screening tools (e.g., portable XRF, PID, etc.,) to check for COPCs if previously collected sample data are not available. Prepare a preliminary assessment of potential environmental concerns at the site with respect to the types of chemicals suspected to have been released and current or anticipated future site use, including possible contamination of both soil and groundwater. Use this information to prepare a preliminary, CSM of contaminated soil and groundwater-related environmental hazards. Additional guidance on the preparation of a CSM is provided in Appendix B.

3.2.2 STEP 2: IDENTIFY SITE INVESTIGATION OBJECTIVES AND CHEMICALS OF POTENTIAL CONCERN

Use the information generated in Step 1 to develop specific site investigation questions related to risk and/or the optimization of remediation. Example questions directly related to risk include:

- What are the specific contaminants of concerns at the site?

- Does long-term exposure to contaminants in soil pose a chronic health risk to site occupants or construction workers or to ecological receptors?

- Do vapor emissions caused by temporary exposure of heavily contaminated soil pose a short- term, acute health risk to workers or nearby residents?

- Do volatile chemicals in contaminated soil pose a risk of vapor intrusion into overlying buildings and adverse impacts to indoor air?

- Do contaminants in soil pose risk of leaching concern and contamination of drinking water resources or ecological, aquatic habitats?

- Do contaminants in the soil pose a potential leaching concern for landfill disposal?

- Do contaminants in soil pose a risk of fire, nuisance odors, sheens on water, fouling of construction equipment or other concerns during current or future site activities?

Example questions related to remediation include:

- What are the lateral and vertical boundaries of contamination above levels of potential concern?

- Where is the main mass of the contaminant located?

- What is the mass of the contaminant in soil targeted for in situ treatment?

- How is the contaminant mass partitioned between free product (nonaqueous-phase liquid), dissolution in groundwater and sorption to soil particles?

Natural soil leaching concerns can be assessed by use of Synthetic Precipitation Leaching Procedure (SPLP Method 1312), soil column leaching method (Method 1314) or, for unpaved areas and aged releases, simple testing of groundwater (HDOH 2024). Leaching risks for soil that is to be disposed of in a landfill is assessed based on the Toxic Characteristic Leaching Procedure (TCLP). Both the SPLP lab protocol (USEPA 1994) and TCLP lab protocol (USEPA 1992) require testing of a minimum 100-gram subsample. Large particles included in the sample submitted to the laboratory should be included in the leaching test. Particles over 0.5 cm in diameter should be manually broken into smaller pieces in order to meet a Fundamental Error of approximately 15% (refer to Appendix D in Section 4). This is because the Investigation Question relates to leaching of contaminants from the soil as a whole. Note that the USEPA lab methods only require breakage of particles to only 1 cm diameter or less. This would result in an unacceptably large Fundament Error, however. Samples should not be milled, since this could bias the leaching tests high.

The latter set of questions are particularly important when the remediation goal is based on a targeted reduction in the mass of contaminant present (e.g., 80%) rather than cleanup to a concentration-based goal.

3.2.3 STEP 3: DETERMINE DATA INFORMATION NEEDS

Evaluate existing site data and determine if additional data or other information are needed. Data needs should be continuously re-evaluated and refined as more site information becomes available and potential hazards are identified.

For example, relatively immobile contaminants like lead, arsenic and organochlorine pesticides primarily pose direct-exposure concerns. Accurate assessment of risk might require additional testing of samples for parameters such as bioaccessibility. Nonvolatile, soluble contaminants like nickel salts and chlorinated herbicides can pose leaching problems and contamination of groundwater. This might require the collection of groundwater data. Volatile and soluble contaminants like petroleum hydrocarbons and chlorinated solvents can pose both leaching and vapor emission concerns. This might require the collection of soil vapor and if necessary indoor air data, if a significant vapor intrusion risk is identified (refer to TGM Section 7). Optimization of remediation can require a greater resolution of the lateral and vertical extent of high- concentration areas of contamination than might otherwise be necessary to simply assess risk.

Risk is always assessed based on the concentration of a contaminant for a designated exposure area and volume of soil as a whole. Sample collection must therefore be designed to directly provide the mean contamination concentration for a targeted DU area and volume of soil.

For example, “Does the true or “mean” concentration of lead for this 5,000 square feet (ft²) area of soil to a depth of four inches exceed the screening level for potential, direct exposure risk under current or future site conditions?” Note that all data for particulate matter represent a mean of the group of particles tested. Although retained for use in this document, use of the term “mean” is redundant and not strictly necessary. This question is addressed by the collection and testing of a representative sample from the designated area and volume of soil. The resulting data are then used to directly answer the investigation questions asked and determine the need for additional actions based on DU-specific “Decision Statement” formulated prior to the collection of samples.

3.2.4 STEP 4: DESIGNATE DECISION UNITS

Decision Unit areas and volumes of soil are designated for sample collection based on the site investigation questions. Examples of DU designation under different site scenarios are provided in Appendix C. Determine the location, size, shape and depth of Exposure Area and/or Source Area DUs based on the potential environmental hazards associated with target contaminants, the intended use of the site and anticipated remediation measures. Designate known or suspected contaminant source areas for individual testing in order to isolate the contamination and optimize remediation. These areas are generally set to tens of square meters to several hundred square meters in size. Designate one or more rings of Boundary DUs around the periphery of the suspected source area(s) to confirm the extent of contamination.

Divide the remainder of the site into Exposure Area DUs based on site usage for testing. If suspected source areas within the site are not identified, then consider dividing the entire site into Exposure Area DUs for testing. The locations and sizes of Exposure Area DUs are site-specific but are typically several hundred square meters in area.

3.2.5 STEP 5: PREPARE DECISION STATEMENTS/JUDGEMENTS

Use the sampling information determined in Step 3 and the DUs defined in Step 4 to write a decision statement specifying the contaminants to be measured and the corresponding measures to be taken during the decision-making process.

Example wording for decision statements includes:

“If the concentration of [chemical substance] in the targeted DU based on [MI sample data value] and analyzed using [analytical method] exceeds [value], then [required action]. If not, then [next steps].”

Actions in cases where published action (screening) levels are exceeded could include removal of contamination above default action levels, designation of areas for capping and long-term management, or development of alternative action levels in a site-specific risk assessment.

It is important that fixed decision statements be assigned to each DU at the beginning of the project and before samples are collected. The decisions statements should be agreed upon by all stakeholders in the investigation, including risk assessors, remediation experts and the overseeing regulatory agency and should consider the time allotted for completion of the project and the budget. Decision statements should be strictly followed when the sample data are obtained.

Decisions Units should be ideally designated at the scale necessary for final decision making from the start. Subdivision of original DUs for resampling after data are obtained and determined to exceed screening levels should be avoided (refer to Fact Sheet #2 in Section 4, Appendix A). This will minimize delays for completion of the project and avoid unanticipated problems due to changes in original plans. Followup subdivision of a site into smaller DUs might be unavoidable in some cases, however. Examples include cases where the responsible party is only willing to initially fund an investigation that focuses on the use of relatively large, Exposure Area DUs to assess risk. If one or more DUs fail action levels, then a decision will be made to abandon the project or proceed with a more detailed investigation. Responsible parties should be made aware of potential project completion delays if this approach is followed and weigh the pros and cons.

3.2.6 STEP 6: DEVELOP AND IMPLEMENT SAMPLE COLLECTION AND ANALYSIS PLAN

Prepare a plan for the collection, processing and testing of samples from the designated DUs. A detailed discussion of the elements of a sample collection and analysis plan is provided in the following sections and in the appendices.

When formulating a sampling plan, consider the challenges that could occur during sample collection, including:

- Availability of to-scale, detailed maps;

- Availability of facilities for equipment staging, decontamination and sample storage;

- Need to clear area of debris and vegetation before sample collection;

- Existing structures and other hindrances to access of targeted sample collection areas;

- Ground surface conditions (e.g., pavement);

- Topography;

- Subsurface debris, cobbles, boulders or bedrock that could inhibit drilling;

- Underground utilities;

- Overhead utilities;

- Depth to groundwater;

- Types of tools required to collect surface and/or subsurface samples;

- Total number of samples to be collected;

- Anticipated total sample collection and analytical costs;

- Laboratory sensitivity/reporting limits and tolerable QA/QC levels; and

- Reasonable allocation of funds.

Multi Increment sample collection methods are required to obtain reliably representative data for a targeted DU. A detailed discussion of the scientific basis of MI sample collection methods is provided in Appendix D. The inherent error in past, “discrete,” “grab” or “composite” sampling methods is discussed in Appendix E. The collection of MI samples from surface and subsurface soil is discussed in Appendices F and G, respectively. Additional guidance on the collection of samples from excavations and stockpiles, samples to be tested for volatile chemicals and the collection of sediment samples is provided in Appendices H through J.

Consult with the laboratory prior to submitting the samples for analysis. Request a copy of the laboratory Standard Operation Procedure for processing and analysis of MI Sample and ensure that they have experience. Discuss quality assurance measures to be carried out by the laboratory to ensure the data are representative of the samples provided. Require the laboratory to include a brief but concise summary of sample processing methods in the report, including the mass of the sample received and the mass of the subsample tested.

3.2.7 STEP 7: ASSESS DATA QUALITY

Review final sample collection and testing methods for consistency with the workplan and requirements for the collection of representative sample data. Review laboratory analytical performance data to assess data quality control associated with subsample testing. Refer to field and laboratory replicate sample data to evaluate the overall data precision (see Section 3.8). Ensure that analytical sensitivity and error are within agreement of the decision statements. Discuss how to address “non detect” result when the Method Reporting Limit or Detection Limit is above the action (screening) level or if a result is very close to the action level but the replicate RSD is higher than desired.

3.2.8 STEP 8: DETERMINE POTENTIAL ENVIRONMENTAL HAZARDS

After completing the data assessment, compare environmental data with environmental screening values or use the data to quantify risk in a risk assessment. Ensure that the risk assessment, also referred to as an Environmental Hazard Assessment, addresses all potential environmental concerns identified in Steps 1 through 3 of the planning process (refer to Section 13 and HIDOH 2017).

3.2.9 STEP 9: IMPROVE CSM AND PROPOSE NEXT ACTION PROPOSAL

Update the CSM based on the data collected and a more in-depth understanding of site conditions and potential environmental hazards. Use the revised CSM to identify any data gaps and determine the scope of work required to complete the site investigation. Prepare recommendations for additional actions when the investigation is determined to be complete and reliable.

Return to the Top of the Page

3.3 DESIGNATION OF DECISION UNITS

The need for remediation of contamination is driven by the identification of a significant risk to human health or the environment. The risk is identified and assessed by designation of risk-based areas and volumes of soil for testing, referred to as “Decision Units” or “DUs.” The proper designation of DUs of soil, sediment or any other environmental media for testing is a critical step in the site investigation process. Refer to Sections 6 and 7 of the TGM for discussion of DU designation approaches for water and air.

Decision Units represent the physical resolution of the site investigation necessary to address questions related to risk and optimization of potential remedial actions. These questions are prepared as part of the initial CSM. Designation of well-thought-out DUs with clear decision statements on how sample data are to be used helps minimize the need for additional sample collection and will expedite overall project completion. Improper designation of DUs during the site investigation stage of a project can result in delayed completion of the site characterization, an inaccurate assessment of risk and inefficient remediation.

A DU can be thought of as the total volume and area of soil that would ideally be sent to the laboratory for testing as a single mass. For example, this might include all of the upper four inches of soil in a 40,000 ft² playground for a total of 500 cyds of soil. In most cases, submittal of such a large mass of soil to a laboratory for extraction is not practical. As an alternative, a representative 1- to 2-kilogram (kg) sample of soil must be collected (Section 3.4). This sample is likely still too large for the laboratory to extract as a single mass and a second, representative subsample must be collected. As discussed in Appendix D, each step introduces error into the final data.

Most DUs are shaped like a thin table, with the length and width of the sides being far greater than the thickness. Such shapes require special attention to the sample collection method employed to represent the targeted area and volume of material. As discussed in Section 3.4, the sample must be collected by combining small masses of material from evenly spaced points throughout a DU. Testing of material from a single point or cluster of points will not generate reliable sample data for decision making.

Soil particle size is an important factor in the designation of DUs. As a default, the <2 millimeter (mm) fraction of material specifically defined as “soil” is normally targeted for testing (USEPA 1996b). This is the fraction of soil assumed to contain the main mass of contaminants and pose the highest environmental risk and, for the purposes of site characterization, is the actual DU. Testing of coarser or finer particle sizes might be required on a site-specific basis. For example, risk assessors might require data for the very fine fraction of soil specifically anticipated to adhere to young children’s hands (e.g., <250 micrometer [µm] or <150 µm; USEPA 2011d, 2016c). Larger particles, including cobbles and gravel as well as rock are not typically considered part of a DU and in general do not need to be tested beyond basic field screening (e.g., observance of stains, sheens when placed in water, odors, etc.). Consider the collection of soil gas samples to assess potential vapor intrusion or leaching risk and direct testing of groundwater for assessment of potential leaching risk.

Samples must be sieved to isolate the targeted particle size. Consider sieving in the field using a #10 sieve the soil is adequately dry or otherwise remove large particles by hand to reduce the mass shipped to the laboratory. If the initially designated DU does not contain soil within the targeted particle-size range, then no sample is collected. For example, if the <2 mm particle size is targeted but particles this small are not present in a stockpile of boulders then the DU of interest does not exist and no sample is collected.

A brief overview of common types of DU designation under different site scenarios is provided below. Additional examples of DUs are provided Appendix C.

Example scenarios include:

- Small- to medium-size commercial and industrial sites;

- New residential housing developments;

- Existing schools;

- Agricultural fields;

- Former industrial complexes;

- Petroleum facilities;

- Buried waste pits and subsurface contamination;

- Excavations and stockpiles; and

- Canals, ponds and streams.

The examples can also be applied to other types of sites, including mining areas.

Although some generalities can be made, the type, size, shape and number of DUs for a particular project is specific to that project and takes into consideration the past, present and future use of the site as well as the objectives of the party carrying out the investigation (refer to Fact Sheet #2 in Section 4, Appendix A). If a contaminant poses multiple potential environmental concerns (e.g., both direct exposure and leaching to groundwater), the smallest DU (i.e., the highest resolution) should be selected to investigate the soil. Different media within the DU (e.g., soil, groundwater, soil vapor, indoor air) should be sampled and tested separately as appropriate to address the investigation questions. If the investigation is being carried out purely for due diligence purposes as part of a property transaction and contamination is not known or suspected to be present, then testing of a relatively small number of large, Exposure Area size DUs might be adequate. The appropriate level of detail necessary to meet the short- and long-term needs of all stakeholders should be discussed with the responsible party prior to completion of the sampling plan.

Previously collected data for samples collected from single points, referred to as “discrete” or “grab” samples, during earlier stages of an investigation as well as unstructured “composite” samples can be used to assist in the designation of DUs for more comprehensive testing but should not be relied on for final decision making (Brewer et al. 2017a,b). A discussion of the limitations of these types of sampling methods is provided in Appendix E.

3.3.1 EXPOSURE AREA DUS

In risk assessment, an area of exposed soil that people regularly come in contact with and that could potentially be contaminated is referred to as an “exposure area.” Examples include parks, playgrounds and unpaved areas of commercial or industrial properties, landscaped areas, and construction worker areas (Figure 3-2; see also Section 4, Appendix C). Individual areas or in some cases the entire area are initially designated as Exposure Area DUs for characterization. Soil capped under a building or parking lot or soil in the subsurface that could be excavated and spread out in the future could be considered to represent future Exposure Area DUs.

Designate Exposure Area DUs based on current land use (e.g., the playground at a school or an unpaved work or eating area at a commercial or industrial site) or future use of the area (e.g., a proposed residential development). The upper two to six inches of soil is normally designated to assess current direct exposure risk. Testing of deeper soil suspected to be contaminated is often required to address potential disturbance of the soil in the future and redistribution on the surface.

If a known or suspect area of contamination is within an Exposure Area DU that could cause the entire DU to fail risk limits, then this area is normally isolated and independently tested as a Source Area DU (Section 3.3.2). This minimizes the need for retesting if a problem is discovered and optimizes the speed and efficiency of remedial actions. If the objective is simply to establish the presence or absence of risk for the Exposure DU as a whole, then subdivision characterization of subareas within the DU is not necessary.

3.3.2 CONTAMINATION SOURCE AREA DUS

Isolation and testing of known or suspect areas of heavy contamination to optimize remediation and reduce risk is an important part of most site investigations. Such areas, referred to as “Source Area” (or “Spill Area”) DUs, should be designated as separate DUs for investigation. Source Area DUs normally fall within and drive risk for larger Exposure Area DUs. Examples of source areas include former chemical storage areas, areas where chemicals were spilled or disposed of during factory operations, former waste pits and layers of buried waste (Figure 3-2).

Contamination designated as localized Source Area DUs at industrial properties often cover an area of only a few tens to hundreds of square meters and can be relatively shallow (thin). Examples include waste sand blast material, lead shot or lead-based paint in the upper few centimeters of soil. In other cases, contamination can extend to considerable depths, particularly for releases of solvents, petroleum or other liquids. The extent of subsurface contamination can also depend on whether the chemical was spilled at the surface, leaked from underground tanks and pipes or was intentionally buried. The suspected duration of the release should also be considered. Slow but long-duration leaks of liquid chemicals from underground tanks and pipes can result in very deep contamination extending to the water table. In case of dense, non-aqueous liquids (DNAPL), contamination can extend to well below the water table.

Exploratory boreholes and pits or trenches can be very useful for initial investigation of contamination in subsurface soils (see Section 3.3.4). Divide subsurface soil into separate DU layers for sample collection and analysis based on the information obtained in the CSM (Figure 3-4). If no obvious contamination or differences in soil type is identified in exploratory boreholes or pits and trenches but confirmation that subsurface soil is clean is required, then consider designation of multiple 0.5 m to 2 m DU layers for sample collection to a depth appropriate for the planned project.

Default DU volumes typically range from 100 to 400 m³ (approximately 100 to 400 cyds). Large DU volumes can be appropriate for due diligence testing of subsurface soil that it not anticipated to be contaminated. This might include, for example, relatively deep soil (e.g., DU-3 in figure) situated below an anticipated clean subsurface Boundary DU (e.g., DU-2) at a site where shallow, surface soil is impacted by releases of lead, PCBs or other relatively immobile contaminants (e.g., DU-1).

Obtaining precise, in situ concentration data for heavily contaminated subsurface soil might not be necessary in cases where the soil will be excavated or managed in place. Confirmation samples can instead be collected after initial remediation or to establish the boundaries of contaminated soil to be left on site. In other cases, high-resolution data for heavily contaminated subsurface soil might be required to estimate the mass of a contaminant and/or to help optimize the design of in situ remediation. Failure to initially obtain representative soil data is the leading cause of unsuccessful in situ remediation actions.

3.3.3 CONTAMINATION SOURCE BOUNDARY AREA DUS

Boundary DUs are used to surround and isolate areas of anticipated heavy contamination. The DUs are designated in anticipated clean or only moderately contaminated areas based on the initial CSM (Figure 3-5).

This helps to minimize the inclusion of otherwise clean soil in subsequent remedial actions and help control project costs.

The number and design of Boundary DUs designated as part of a project is site- and project-specific. In the case of the example depicted in Figure 3-5, the boundary between heavily contaminated soil and anticipated clean soil was clearly evident in the field and there was high confidence that the Boundary DUs would indeed be clean. In other cases, designation and testing of two or more rings of Boundary DUs might be desired in the event that the innermost DUs fail screening levels.

Vertical delineation of contamination should similarly be determined based on designation and testing of vertical Boundary DU layers. If necessary, the extent of subsurface contamination can be initially approximated using exploratory borings, pits or trenches (refer to subsurface investigation guidance in Appendix G). Limitations of testing of single cores of soil and the potential for both false negatives and false positives with respect to the large-scale assessment of risk and remediation needs must be considered. More reliable DU sampling methods and data should be used to confirm the boundaries of identified or suspect source areas. Designate boundary DU sizes in a manner that will optimize potential remedial actions but avoid the need for remobilization for collection of additional samples if action levels are failed.

3.3.4 EXCAVATIONS AND STOCKPILES

Detailed guidance on testing of excavation sidewalls and stockpiles is provided in Section 4, Appendix H. Guidance on testing of stockpiles or other sources of imported fill material is provided in Section 4, Appendix P.

The walls and floor of an excavation should be designated as separate DUs for sample collection (Figure 3-6). Lateral and vertical Boundary DUs are designated to confirm the removal of a source area of contaminated soil. Multiple DU layers may need to be designated within a DU wall to target specific layer intervals of contamination. It may also be necessary to divide the floor of the excavation into multiple DU areas to confirm the vertical cleanup of contaminated soil. Such decisions must be made on a site-specific basis.

The concept of Exposure Area and Source Area DUs also applies to testing of stockpiles of excavated soil. Designation of DUs for stockpiles, in contrast, based on the risk-based volume of soil associated with the anticipated reuse, for example reuse as fill in a residential redevelopment project (resident exposure risk) or disposal at a landfill and reuse for daily cover (worker exposure risk). Example risk-based volumes of soil are presented in Table 3-1. Additional guidance on the designation of DUs and the collection of samples from stockpiles is provided in the appendices. This approach can also be used for testing of stockpiles of dredged sediment that is proposed for reuse as fill material.

Table 3-1. Example default DU volumes for stockpiles.

| Receiving Site Land Use | ¹Default DU Volume | Notes |

| Unrestricted Use (includes small parks and low-density, residential developments with individual yards) | 100 cyds | Assumes approximately 5000 ft² reuse exposure area and 6″ placement thickness. |

| Schools and High-Density Residential Developments | 400 cyds | Assumes approximately half-acre exposure area and 6″ placement thickness. |

| Commercial or Industrial use only (including agricultural lots) | 400 cyds | Assumes approximately half-acre exposure area and 6″ placement thickness. |

| 1. Testing of 100 cyd DU volume of soil is anticipated in most cases to identify potentially significant vapor intrusion and/or leaching concerns. Use of smaller DUs volumes as well as the collection of soil vapor data and/or used of laboratory-based methods to assess leaching risk might be required on a case-by-case basis. Note that this updates and takes precedence over recommendations to use a 20 cyd DU volume for assessment of leaching risks in the 2017 HIDOH Clean Fill guidance. | ||

Larger DU volumes up to several thousand cubic yards might be acceptable for stockpiles of soil or dredged sediment when the origin of the soil is well known and there is no reason to suspect significant contamination. Examples include excess soil generated during construction on previously undeveloped land or dredged sediment from areas not susceptible to contamination. Some level of minimal testing in this case is often desirable for legal due diligence purposes.

When investigating stockpiles, large stockpiles should be separated or split into separate piles based on soil type, source, potential for contamination, potential environmental concerns associated with targeted chemicals (e.g., direct exposure or leaching) and proposed reuse of the oil. Stockpiles of soil are normally flattened and divided into DU volumes for testing using the same concepts of source areas and exposure risk as applied to testing of in situ soil (Figure 3-7). Alternative methods for sample collection where pile cannot be flattened are discussed in Appendix G.5 and Appendix H. This includes incremental testings and clearing of soil and accessible faces of a stockpile and excavation of small “windows” and trenches to access interior areas of a pile.

Consideration of the “fluff factor” and larger volumes can be made for stockpiled ex situ soil that will be compacted during use as fill material. Allowances for larger DU volumes can be made for deeper material not known or suspected to be contaminated (e.g., native soil) as well as sediment to be dredged from areas that lack known sources of potentially significant contamination, where testing is primarily for due diligence purposes. Refer to Appendix H for additional guidance.

Figure 3-7. Example flattening of a soil stockpile and division into risk based DUs for sample collection. Trenches, pits or other types of “windows” can be cut into stockpiles to assist in sample collection when space is not available for flattening the pile.

3.3.5 SEDIMENT DECISION UNITS

Decision Unit and Multi Increment Sample investigation methods are used for characterization and remediation of contaminated sediment in a similar manner as described for soil. Examples include the investigation of direct-exposure risk to benthic and aquatic organisms and in situ or ex situ characterization of dredge material for reuse as fill in upland areas or for offshore or onshore disposal.

Designate DUs based on risk to ecological receptors or optimization of anticipated dredging or in situ remediation actions. Ecological risk is assessed based on exposure to benthic organisms as well as factors such as particle size for open water disposal. Human health risk associated with upland reuse of dredged sediment as fill material in the same manner as described for stockpiles and Exposure Area DUs.

Example investigation questions that can be used to designate DUs for assessment and sample collection include:

- Is the sediment within this specific DU area of the lake, river, canal, etc., contaminated above levels of potential concern?

- What is the lateral and vertical extent of contamination above levels of potential concern?

- Is contamination restricted to specific depositional areas of sediment?

- Do risk-based DU volumes of sediment proposed for dredging or already dredged and stockpiled material meet comparable risk-based screening levels for proposed reuse in upland areas?

Specific areas and volumes of sediment must be assigned to each investigation question. In some cases, a single DU might be adequate. In other cases, designation of multiple DUs might be required.

Dredging projects can generate very large volumes of sediment desirable for use as fill material in upland areas. DU volumes up to 800 cyds or greater might be acceptable for testing of sandy sediment not located in the proximity of a contaminant source and lacking in significant, fine-grained material potentially associated with contamination imported by currents. Examples include dredging of mobile sand bars in rivers and tidally influenced areas. Fine-grained sediment in harbors, canals and similar low-energy bodies of water that are highly susceptible to releases of contaminants will normally require testing of much smaller DUs to optimize costs associated with offshore or onshore disposal or in situ remediation.

For proposed upland reuse of dredged material, DU volumes should reflect the potential exposure scenario in relation to the proposed area size and placement thickness. For example, the dredged sediment is proposed to be reused as fill material at a planned one-acre soccer field. In this case, the exposure is assumed to be primarily a concern for the upper 6” of soil, for a total approximate volume of 400 cyds. Larger DU volumes might be acceptable depending on reuse area and assumed uniformity of contaminants within the sediment (refer to case studies in Appendix C).

As discussed in the harbor dredging case study in Appendix C, sample collection can be carried out in situ, during dredging or after the dredged material has been placed in stockpiles. The most optimal strategy for a specific project will depend on factors that include accessibility and availability of cost-effective methods for in situ sample collection and the availability of space for stockpiling as well as time constraints for ex situ sampling.

Return to the Top of the Page

3.4 SAMPLING AND ANALYSIS PLANS

3.4.1 SAP OUTLINE

The Sampling and Analysis Plan (SAP), developed during Step 6 of systematic planning, specifies the final design and configuration of the environmental measurement effort required to resolve issues and questions stated in the systematic planning steps (Steps 1-5). The SAP is a comprehensive document that would enable an experienced field sampling team unfamiliar with the site to come in and examine the site and collect the required samples and field information. The SAP designates the types and quantities of samples or monitoring information to be collected; where, when and under what conditions they should be collected; the variables to be measured; and the Quality Assurance/Quality Control (QA/QC) procedures to ensure that sampling design and measurement errors meet the tolerable decision error specified.

The QA/QC procedures are described within the Quality Assurance Project Plan (QAPP), which is included within the SAP. The site-specific Health and Safety Plan is also included as part of the overall SAP (alternately, the Health and Safety Plan can be presented with the SAP in a site Work Plan). The SAP must be flexible and dynamic to deal with unexpected discoveries or circumstances that may be encountered during the site investigation. To ensure appropriate characterization of the site and to minimize the need to perform additional sampling, it is recommended that SAPs be reviewed and approved by the HEER Office. In addition, it is important to consult with the laboratory while developing the SAP to ensure objectives are in alignment with chosen laboratory practices, and to provide contingencies for matrix problems that may occur. Important among such issues to discuss with the laboratory are expectations for storing remaining portions of MI samples that have been analyzed, until site sampling decisions are completed. Based on initial data analysis or new information, additional analyses may be conducted from stored bulk MI samples rather than having to mobilize and collect additional samples in the field.

The suggested outline for the SAP is as follows:

| I. Introduction | VI. Description of Sampling Activities |

| II. Site Background | VII. Analytical Methods |

| a. Site description | VIII. Quality Assurance Project Plan |

| b. Site characteristics | IX. Documentation and Reporting |

| III. Investigation History | X. Schedule |

| IV. Site Investigation Objectives | XI. Health and Safety Plan |

| V. Scope of Work | XII. References |

More detailed information regarding the outline, format, and required content of the SAP is presented in https://health.hawaii.gov/heer/tgm/section-18/” target=”_blank” rel=”noopener noreferrer”>Section 18.

3.4.2 SAMPLE COLLECTION STRATEGY

A sampling strategy should reflect the approach that will best meet investigation objectives within acceptable uncertainty limits, with consideration taken for efficient use of time, money, and human resources. Section 4, Appendix D discuses sample collection strategies for soil and sediment.

The HEER Office strongly encourages the use of Multi Increment/Decision Unit strategies to investigate contaminated soil. Multi Increment samples are collected using a probabilistic sampling theory and involve the collection of a large number of increments (30-100) from within the target DU. Each increment is made up of approximately 5 to 50 grams of soil. The increments are combined to form a single, Multi Increment sample for the DU. A detailed discussion of Multi Increment sampling approaches is provided in Section 4, Appendix D.

See Section 6 for sample collection strategies for groundwater, and Section 13 for information and references regarding ecological risk evaluations.

3.4.3 HEALTH AND SAFETY PLANS

Hawai’i hazardous substance release sites fall under the definition of “uncontrolled hazardous waste sites” pursuant to Occupational Safety and Health Administration (OSHA) Hazardous Waste Operations and Emergency Response (HAZWOPER) Title 29 Code of Federal Regulations (CFR) Section 1910.120(a)(1). A health and safety plan (HASP) is required under Title 29 of the Code of Federal Regulations, Section 1910.120 (Hazardous Waste Operations and Emergency Response), which includes a requirement for a hazard communication program meeting the requirements of 29 CFR 1910.1200. Like rules were adopted under Hawaii Administrative Rules Title 12 Department of Labor and Industrial Relations Subtitle 8 Hawaii Occupational Safety and Health Division Part 2 General Legal and Administrative Provisions for Occupational Safety and Health Chapter 60 General Safety and Health Requirements and Hawaii Administrative Rules Title 12 Department of Labor and Industrial Relations Subtitle 8 Division of Occupational Safety and Health Part 8 Health Standards Chapter 203.1 Hazard Communication. The Health and Safety plan is typically a part of the SAP (or alternately, part of the site Work Plan). The HEER Office recommends that an employer develop a written Health and Safety Plan, which includes the following elements:

- An organizational structure

- A comprehensive work plan

- A site-specific health and safety plan

- A health and safety training program

- A medical surveillance program

- Standard operating procedures for health and safety

- Any necessary interface between general program and site-specific activities

The OSHA HAZWOPER Standard, Title 29 CFR 1910.120, requires that personnel working in and around hazardous waste have a site-specific HASP and competent safety officers to enforce health and safety rules. OSHA has determined that employees must be trained if they work in proximity to hazardous chemicals with a potential for release or substantial threats of release, without regard to the location of the hazard.

An OSHA-certified 40-hour class focusing on HAZWOPER training is required for those who are performing regular work on hazardous waste sites; an annual 8-hour refresher course is required to maintain the certification achieved through this training. An OSHA-certified 24-hour course is required for those who have occasional exposure to hazardous waste. In addition, an 8-hour course is required for supervisors and management personnel who oversee hazardous waste projects. The amount of training required is contingent upon an employee’s responsibilities and involvement with hazardous materials; these must be clearly established by the employer and communicated to the employee(s). The HEER Office does not approve Health and Safety Plans but does require that one be in place for field activities at hazardous chemical release (or suspect release) sites. Contact the Hawai`i Division of Occupational Safety and Health (HIOSH) for detailed information on HASPs and organizations offering HAZWOPER training.

3.4.4 QUALITY ASSURANCE PROJECT PLANS

Data acceptance criteria, developed during Step 5 of systematic planning, are presented in the Quality Assurance Project Plan (QAPP) which is the formal project document that specifies the operational procedures and QA/QC requirements for obtaining environmental data of sufficient quantity and quality to satisfy site investigation objectives. The QAPP is required for all data collection activities that generate data for use in decision-making. It contains information on project management, measurement and data acquisition, assessment and oversight, and data validation and usability. The QAPP integrates the DQO, the data collection design, and QA/QC procedures into a coherent plan to be used for collecting data that are of known quality and adequate for their intended use. The QAPP is typically presented as part of the SAP (Step 6 of systematic planning) and should include the following elements:

- Quality assurance (QA) objectives for measurement

- Sample chain of custody

- Calibration procedures

- Analytical methods

- Data reduction, validation, and reporting

- Internal quality control (field and laboratory checks)

- Performance and system audits

- Preventative maintenance

- Data measurement assessment procedures (precision, accuracy, and completeness)

- Corrective actions

Participation of the laboratory that will be utilized is important to ensure capabilities are agreed upon and not assumed. Other considerations such as potential changes to cleanup processes, lab filtration, etc. should be discussed ahead of time when potentially contaminated samples are collected.

More detailed information regarding the outline, format, and required content of the SAP, which includes the QAPP, is presented in Section 18.

Additional information regarding the development of a QAPP is available in the Uniform Federal Policy for Quality Assurance Project Plans (USEPA/DoD/DOE 2005), Guidance for Conducting Remedial Investigation and Feasibility Studies under CERCLA (USEPA 1988), and Guidance for Quality Assurance Project Plans (USEPA, 2002g). In addition, Data Quality Assurance and Quality Control procedures are discussed in detail in Section 10.

Return to the Top of the Page

3.5 SITE INVESTIGATION REPORTS

Accurate and thorough documentation of the sample plan design, sample collection and handling procedures, laboratory analyses, data assessment, and a summary of the data collected are crucial to the site investigation. The laboratory selected should adhere to a comprehensive Quality Assurance Plan and SOPs for sample analyses. The HEER Office strongly encourages active communication, including draft report reviews and subsequent meetings or conference calls, to prevent costly remobilizations to collect additional data. The following reports (and major elements) are typically prepared and submitted to the HEER Office for review.

- Sampling and Analysis Plan

- Sampling design

- Preliminary Conceptual Site Model

- Preliminary site investigation objectives and DQO

- QAPP

- Safety and Health Plan

- Site Investigation Report

- Site history

- Site investigation objectives (including DQO)

- Selection of Decision Units, including replicates

- Figures displaying all DU locations on site

- Identification of information needs

- Sample collection and analysis methods

- Summary of analytical results

- Data assessment

- Summary of extent and magnitude of contamination

- Preliminary Environmental Hazard Evaluation

- Conclusions and recommendations

Additional guidance on report formats and content is presented in detail in Section 18. The HEER Office requires that the lateral and, as needed, vertical extent of soil and groundwater (and in some cases soil gas) contamination be clearly depicted on to-scale maps and cross sections of the site. Shading or other graphics should be used to depict DUs suspected to be contaminated above levels of potential concern. This information is then used in the Environmental Hazard Evaluation to identify specific environmental hazards posed by the identified contamination as well as the specific areas of the site where these hazards are present (see Section 13). The results of the preliminary Environmental Hazard Evaluation may require that additional data be collected at the site (e.g., soil gas data to evaluate potential vapor intrusion concerns) or that additional tests be carried out on existing samples. After all environmental hazards are adequately identified, delineated and evaluated, the final Site Investigation and Environmental Hazard Evaluation reports are used to support and assist in the development of appropriate response actions.

Not all projects will require that formal sampling plans and related reports be submitted prior to initiating site investigation activities; this will vary from site to site and should be discussed with the overseeing project manager in the HEER Office.

Return to the Top of the Page

3.6 DECISION UNIT CHARACTERIZATION

3.6.1 USE OF MULTI INCREMENT SAMPLES TO REPRESENT DUS

Risk is always assessed based on the “true” or “mean” concentration of the contaminant in each subject DU (USEPA 1987, 1988, 1989b, c, e, f, 1991g, 1992c, 2014f). The objective of sample collection is therefore always to estimate the concentration of the contaminant for the targeted DU volume of soil or sediment as a whole. Ideally, the entire DU volume of soil would be removed, taken to a laboratory for testing and the concentration of the subject contaminant for the volume of soil as a whole determined. This is not normally possible, however, and a representative sample of the targeted area and volume of soil must instead be collected.

Obtaining reliable data requires that both the sample in the field is representative of the targeted DU area and volume of soil and that the subsample collected for testing at the laboratory is representative of the sample submitted. This is most efficiently accomplished through the collection of a single MI sample from each DU (HDOH 2016). A sample is prepared by collecting and combining a large number of small masses or “increments” of material throughout the entire DU area and volume of soil or sediment (Figure 3-8). The science background and use of MI sample collection methods is based on Pierre Gy’s Theory of Sampling (Pitard 2019). A detailed review of Gy’s sampling theory is provided in Appendix D.

Detailed guidance on the collection of MI samples from surface and subsurface soil as well as excavations and stockpiles is provided in Appendices F through I. The collection of sediment samples is discussed in Appendix J. Processing and testing of MI samples is discussed in Appendix K.

The largest source of error in environmental data is associated with the collection of soil or sediment samples in the field, followed by the collection of subsamples for testing at the laboratory (Pitard 2019; Esbensen 2020). Error associated with analysis of the subsample by the laboratory is typically small by comparison. Field sample and laboratory subsample collection error is controlled by ensuring that an adequate number of increment collection points are utilized and that an adequate total mass of material is collected (refer to Appendix D).

Strong attention to detail is required to collect, process and test a sample in a manner that ensures representative data. Independent replicate samples are collected from a portion of the DUs tested for a specific project (Appendix L). Types of replicate sample data that should be generated for all projects include (see Section 3.6.5):

- Field Sample Replicates (minimum two from at least one DU; tests the overall precision of the total sample collection, processing and analysis methods);

- Field Subsample Replicates (minimum two from at least one DU Layer; tests the precision of subsampling methods required to reduce sample mass for samples prepared from subsurface borings);

- Laboratory Subsample Replicates (minimum two for at least one sample if subsampling of increments is carried out in the field as often required for subsurface investigations; tests the precision of method used by the laboratory to collect a subsample from a field sample for analysis); and

- Laboratory Analytical Replicates (minimum one for each set of samples; tests the precision of the equipment used to analyze a subsample).

Although the collection and testing of field and laboratory replicates adds to the cost of an investigation, the results are critical to demonstrate the reproducibility of the data and defensibility of decisions made. Sample data can only be assumed to be truly representative if the samples were collected properly in the field to begin with (refer to Appendix D).

Additional information on General Field Operations is provided in Appendix M, including field documentation, equipment preparation and decontamination, disposal of investigation derived waste and completion of field work. Common mistakes made in the field and laboratory and that can be reflected by highly variable replicate sample data are discussed in Appendix N. Guidance on the investigation of contaminated soil and sediment under the Toxics Substances Control Act (TSCA) is provided in Appendix O.

3.6.2 SAMPLE MASS, INCREMENT NUMBER, QUALITY AND DISTRIBUTION

Field Sample and Laboratory Subsample Mass

Gy’s Theory of Sampling and experience in the field indicates that a minimum total field sample mass of 1 to 3 kg is necessary to reliably represent the tens, hundreds or even thousands of metric tons of soil incorporated into a DU (Brewer et al. 2017a, b; Walsh 2020). This is intended to address both potential errors associated with the physical nature of the soil or sediment as well as error associated with the collection of sample increments in the field (refer to Appendix D). The mass of increments should remain consistent between collection points and be adequate to achieve the target bulk sample mass after combination into a single sample. For example, the preparation of a 1 to 3 kg 50-increment sample requires an increment mass of 20 to 60 grams.

The final bulk mass applies to the targeted soil particle size and should consider potential sample loss from sieving and the dampness of the soil or sediment. This is not normally an issue for soil but can require the need for a larger sample of saturated sediment in the field, particularly if the sample contains a large amount of fined-grained, clayey material.

A minimum sample mass of 300 grams is recommended for samples to be tested for volatile chemicals (Appendix I). Samples might be prepared, for example, by combination of 60, five-gram increment plugs from excavation sidewalls or from subsurface cores (Appendix I). A smaller bulk sample mass is acceptable due to an expected, more uniform (but still heterogeneous) distribution of liquid volatile contaminants in soil within source areas. Larger samples to be tested for volatile chemicals should be collected, if possible, to increase the representativeness of the data. Refer to Appendix I for guidance on alternatives to the collection of soil samples for assessment of risks posed by volatile chemicals.

Alternative preservation methods for soil samples to be tested for volatile chemicals are discussed in Appendix I. Note that soil data for volatile compounds are most efficiently used to estimate the mass of the contaminant present within a DU as a tool to assist in the design of remedial efforts. The primary environmental risks associated with volatile chemicals are vapor intrusion into overlying buildings and/or leaching of the contaminant into underlying groundwater. In both cases, the collection of soil gas sample data can serve as more directly applicable alternative to soil sample data, provided that soil gas-based action/screening levels are available or can be developed for comparison (refer to Section 13 of the TGM; see also HIDOH 2017).

An ideal analytical subsample mass of 30 grams is recommended to control Fundamental Error associated with <2mm particle size material as well as error associated with the collection of material from a processed sample. If a maximum 10-gram subsample is necessary, then consider the collection of additional subsample replicates in order to better assess error in the data (refer to Section 3.6.5). A ten-gram subsample is adequate for <250µm material. Sample processing and subsample collection methods, normally carried out at a fixed laboratory, are discussed in Appendix K.

Number of Sample Increments

The number of increments necessary to reliably represent a targeted DU area and volume of soil or sediment depends on the distributional heterogeneity of the contaminant within the DU. Statistical analysis of data from field studies indicate that as few as 30 increments per sample can be adequate for characterization of soil impacted by airborne or waterborne contaminants, including stack emissions from a smelter, application of water-based pesticides to field areas or testing of sediment (Brewer et al. 2017a, b; Walsh 2020). A minimum of 75 increments per sample is recommended for cases where the contaminant is present as small nuggets or chips. Examples include polychlorinated biphenyls (PCBs) derived from construction debris or waste oil, fragments of lead-based paint and fragments of lead related to munitions. A default minimum of 50 increments per sample is recommended for the investigation of soil where the nature of the contamination is uncertain.

A larger number of increments might be necessary due to the sample collection method used. For example, the collection of 60 plugs/increments of soil are required to meet the minimum mass requirement of 300 grams if a small syringe is used to collect five-gram plugs of soil from an excavation floor. As an alternative, two side-by-side, five-gram plugs could be collected and combined as a single increment from each of 30 points in the DU face.

The sample increment requirements apply to both surface and subsurface soil and sediment. The fact that the targeted DU layer of soil or sediment is covered with other soil or sediment (or water) does not alter the need to adequately capture and represent distributional heterogeneity. Consider designating a larger number of boring/increment locations than needed for adequate sample preparation as part of subsurface investigations where areas of refusal due to large rocks or other interferences are anticipated. Nonetheless, achieving an optimal number of increments per sample for testing of subsurface samples might in some cases not be possible due to access and budget limitations. Consider designated extra core increment collection points at sites where refusal in some areas is anticipated due to the potential presence of rock, subsurface utilities or buried debris. As discussed below and in Appendix G, data based on samples prepared from less than 30 increments should be considered suspect. Follow-up testing should be carried out if the soil is excavated or otherwise exposed in the future.

If a significant discrepancy between replicate sample data is observed and determined to be based on field error, then the collection of new samples might be required (refer to Appendix L). If this is the case, the number of increments collected per sample and the total mass of the sample should be increased. The original DU could in theory be subdivided into smaller DUs for retesting in order to better isolate subsequently identified areas of known or suspected higher contamination. Redesignation of DUs after initiation of a project is discouraged, however. Designation of DUs should be based on risk or optimization of anticipated remedial actions, not simply in an effort to improve sample data quality.

Increment Quality

The physical collection of sample increments is briefly reviewed in Sections 3.4.4. Detailed guidance on the collection of sample increments in the field under different site and contaminant scenarios is provided in Appendices F through I. The collection of subsamples at the laboratory for analysis is discussed in Appendix K.

The quality of individual increments depends on the shape, mass and uniformity of each increment. Increments should be core shaped and of sufficient mass to meet the minimum target bulk MI sample mass requirement. Ideal increments are core shaped and collected from the entire thickness of the targeted DU layer.

Increment Spacing and Location

Spacing increment collection points evenly throughout the DU both laterally and vertically is important to ensure that sample data are representative and reproducible. A systematic random method of increment placement is recommended (Figure 3-9). Increment locations are arranged in a grid cell pattern with a fixed interval, starting from a random point in one corner the DU. Subsequent increments are collected from the same location in all remaining cells. This applies to the collection of both surface and subsurface increments. Refer to Appendix N for common problems associated with increment spacing in the field.

An initial estimate of adequate increment spacing is calculated taking the square root of the DU area divided by the targeted number of increments to be collected:

This simulates division of the DU into individual, increment collection cells, with a single increment collected from the center of each cell. After calculating the square root of this area, the length of each side of the cell is obtained (assuming square cells).

Refer to Table 3-2. For example, assume a 5000 ft² DU and the desired collection of a 50-increment, sample. The calculated increment spacing is 10 feet. This reflects the assumption that the DU is divided into 50 square cells with 10 foot sides and area of 100 ft². A sample is prepared by collecting an increment from a random point within a cell, such as the center and then 10 feet parallel to the DU boundary to the same point in the adjacent increment cell. This is continued until an increment has been collected in each of the 50 hypothetical cells. The increments are progressively combined into a single bulk sample as they are collected.

Table 3-2. Example Increment spacing based on DU size and target number of increments (meters).

| # Increments | Decision Unit Area (acres) | ||||||||

| 0.10 | 0.20 | 0.25 | 0.50 | 1.0 | 2.0 | 3.0 | 4.0 | 5.0 | |

| 30 | 12 | 17 | 19 | 27 | 38 | 54 | 66 | 76 | 86 |

| 40 | 10 | 15 | 16 | 23 | 33 | 46 | 57 | 66 | 73 |

| 50 | 9 | 13 | 15 | 21 | 29 | 41 | 51 | 59 | 66 |

| 75 | 8 | 11 | 12 | 17 | 24 | 34 | 41 | 48 | 54 |

| 100 | 7 | 9 | 10 | 15 | 21 | 29 | 36 | 41 | 46 |

This approach applies to both rectangular and irregular-shaped DUs. The spacing can be adjusted as needed to help establish a manageable grid for sample collection, provided that an overall systematic random increment collection method is maintained. Examples of proper and improper increment collection patterns are included in Appendix F.

3.6.3 SAMPLE COLLECTION AREA PREPARATION

Remove Surface Debris and Vegetation

Site preparation activities are discussed in Appendix F. A site inspection should be performed prior to mobilizing to collect samples to determine if debris or vegetation needs to be removed. This might include temporary removal of stored material, automobiles and other equipment as well as cutting grass and removal of other low vegetation.

If surface soil is targeted for sampling, then care must be taken not to disturb the soil immediately below the root zone of the vegetation during site clearing activities. If soil within the root zone is targeted, then care must be taken to only remove vegetation directly above the ground surface. Bulldozers or similar equipment should normally not be used to scrape the ground surface since contaminated soil could become mixed with grubbed material. For testing of very large, heavily vegetated areas, consider surveying and clearing narrow, equally spaced transects that correspond to the desired spacing of increments for the DU.

Clear Underground Utilities

Sources for information on the presence of underground utilities, tanks, waste burial pits or other features of the site should be reviewed. These underground features and utilities could interfere with subsurface sample collection or pose a danger to either the utilities or samplers.

Example sources of information include:

- Information provided by public utility companies;

- Call before you dig (https://call811.com/);

- Maps that depict underground water, sewer, electric, gas, fiber optic and other utilities, as well as irrigation lines, buried tanks and pipeline, former building foundations, etc.;

- Interviews with site workers; and

- Field observations if manhole covers, vent pipes, piping and other signs of possible subsurface infrastructure or buried material.

The specific location, arrangement and depth of underground utilities must be determined to the degree possible and marked at the surface to assist in the placement of subsurface borings. Toning methods such as electro-magnetic/radio frequency technology should be considered for sites where subsurface utilities are suspected but the exact locations are unknown.

3.6.4 COLLECTION OF SOIL SAMPLES

Detailed guidance on the collection of MI samples from surface soil, subsurface soil, excavations and stockpiles, sediment and the collection of samples to be tested for volatile chemicals is provided in the Appendices F through I. A brief overview of sample collection methods is provided below. For the purposes of this guidance, the term “soil” is applied to any type of unconsolidated particulate matter. Larger particles, including cobbles and gravel as well as rock are not typically considered part of a DU and in general do not need to be sampled beyond basic field screening (.e.g., observance of stains, sheens when placed in water, odors, etc.).

Proper selection of sampling tools is crucial. The tools utilized must ensure that the soil increments are core- shaped or otherwise have no depth bias to the extent possible and that the mass of individual increments collected is relatively equal. The total mass of the combined increments must be sufficient to achieve the target minimum mass of the MI sample to be collected. “Discrete” samples or “composite” samples that do not meet the strict quality criteria of MI samples should never be used for final decision making purposes (refer to Appendix F).

Be aware that not all laboratories are set up to carry out MI sample processing and analysis. Contact the laboratory ahead of time to discuss sample processing and analysis requirements. Ensure that the lab can meet the requirements for sample preparation and minimum sample mass. If available, obtain a copy of the laboratory’s Standard Operation Procedure for management of MI samples for your records.

Surface Soil

A detailed discussion of methods and tools to collect MI samples from exposed surface soil under different site conditions is provided in Appendix F. The sample collection team progressively moves through the DU to individual increment collection points until the preparation of the sample is completed (Figure 3-10).

Increment collection can range from relatively easy for loose, fine-grained soil exposed at the surface to very difficult for gravelly or hard-packed soil. A variety of tools can be used to collect surface soil samples. The most appropriate tool is selected based on soil type, compactness, rock abundance and targeted increment depth.

Soft Soil. For soft soil, samples are usually collected using sampling tubes or similar manual coring equipment (depicted in Figure 3-10). Small-diameter sampling tubes (one to two inches) are simple, fast and efficient and suitable for a one- or two-person field team. Larger-diameter sampling tubes (more than two inches) will in most cases result in increment masses larger than the amount needed to prepare a 1 to 3 kg bulk sample. While larger samples might be more representative, secondary subsampling in the field could be required to prepare a final sample mass that can be managed by the laboratory. This will introduce additional error into the resulting data.

Loose, dry soil. A flat-bottomed trowel or similar tool might be required for the collection of increments from loose, dry soil (e.g., dry sand or silt). The tool should have a straight, front edge and perpendicular, square sides.

Semi-compact, fine-grained soil. For semi-compact, fine-grained soils, a power drill equipped with an auger bit that has a hollow center flute can significantly expedite the collection of increments (e.g., SpeedBore bits; refer to Appendix F). A one-inch hollow auger drill bit produces 30 to 50 g of soil for every six inches (15 cm) of drilling. The use of drills with standard winged bits should be avoided since they are less efficient at soil removal and can result in oversized increment masses.

Moderately compacted soil. A hand-held, battery-powered drill equipped with a small, spade bit can be very efficient for loosening soil at increment collection points and collecting samples in moderately compacted soils.

Significantly compacted or gravelly soil. A hammer drill with a cement bit or spade bit connected to a portable generator or a manual pickaxe or heavy rock hammer is usually required for the collection of increments from significantly compacted or gravelly soils. In these cases, the bit is used to create an opening and use a trowel to collect an increment from the exposed sidewall. See Appendix F for addition guidance and examples.

Subsurface Soil

A detailed discussion of methods and tools to collect MI samples from subsurface soil is provided in Appendix G. Identical requirements for the collection of high-quality, representative samples from surface soil apply to subsurface soil, with the added field factor that overlying soil must be penetrated to collect increments and prepare samples. The subsurface soil is first subdivided into individually targeted DU layers (Figure 3-11). Ideally, a 1 to 3 kg, 30- to 75-increment sample is collected from each layer.

When site conditions allow, direct-push drill rigs are very efficient for the rapid collection of samples from subsurface soil (depicted Figure 3-11). The rigs can also be used to collect soil gas and/or groundwater samples, if needed. Each core extracted from a targeted DU Layer represents a single increment for that layer, similar to the collection of individual, core-shaped increments from surface soil.

Use a measuring tape and/or soil characteristics used to designate each DU layer to identify targeted DU layers in a core increment (Figure 3-12). The mass of a single core increment is usually too large to be used for the preparation of a manageable sample. The field collection of a representative subsample of adequate mass (e.g., 20 to 60 g) from each DU layer increment is therefore required. For example, this can be achieved by collection of a long, thin wedge from the entire length of the DU layer increment. This might not be possible for gravelly soils. An alternative is to collect four to ten, evenly spaced, five-gram plugs of soil along the entire interval of the increment (depicted in Figure 3-12). Core increment subsamples corresponding to the same DU layer are combined on site to prepare an MI sample for that layer, similar to the approach used to prepare a sample of surface soil.

Be aware that direct-push methods often compress soil and the resulting core may be shorter than expected, if so scale the size of each DU depth accordingly. Also avoid the first inch or so of soil in each DU depth interval as it tends to contain slough from the previous DU interval.

A backhoe can be used to dig potholes or trenches at increment collection locations for testing of soil within approximately 1.5 m of the surface (Figure 3-13). This approach might be necessary for soil that contains large rocks or other obstacles where a direct-push rig otherwise cannot be used. An increment can be collected from each targeted DU layer by using a trowel to scrape a continuous mass of soil from the exposed excavation wall. Samples must be collected with care to ensure that the spacing between increments is equal both laterally and vertically across the DU. As is the case for borings, each pit represents a single increment collection location. Multiple increments cannot be collected from a single pit, since the spacing between points in pits is likely to be much smaller than the spacing between increments from separate pits.

The installation of 30 or more borings or test pits to prepare MI samples for subsurface DUs might not be feasible for some projects due to access, cost or other limitations. In these cases, the reliability of the sample data is limited and the soil should be retested if exposed or excavated in the future.

Single exploratory borings can be used to identify the approximate presence or absence of contaminated subsurface soil (Figure 3-14). Use changes in soil type, the presence of debris, staining and/or odors to designate individual DU layers for testing in each core. A portable XRF and other screening test methods can also be used screen cores and initially test samples in the field.